Efficient optical measurements

Todays demand for many optical applications is in research, development, production and quality control. As different topics as laser beam diagnostics, spectroscopy and measurements tasks of all kind have thereby one in common: optical data analysis with a CCD-linescan camera.

The linescan cameras offer

- High resolution and long length.

- Simple data processing:

- i.e. edges or maximums, can be determined easily after the reading of a line.

- Independence from video system frequencies and therefore freely selectable exposuretime.

- Moved objects can be scanned linewise so that the 2nd dimension is recorded (scanner principle).

- No need for extra mechanic moving parts.

- Simple robustly system design and construction.

- Simultaneously exposure of all pixel.

Easy interface technology:

The cameras contain the complete electronic and control circuits. The interface to the computer is a fiber link for high speed transfer. So the value of each pixel ('picture element') is transferred successively to the computer.

The advantages are:

- Standard PCIE Interface for all desktop PCs.

- High speed PCIE Interface for real time applications.

- High data transfer rate directly to the main RAM of the computer.

- Pixel synchronous transfer:

because the sensor is clocked by the computer, the count synchronisation of the pixel index is -unlike video frequency systems- guaranteed up to the last pixel. - computer interface without additional memory ('Frame Grabber') - you just use the RAM your PC has build in.

- Freely selectable exposuretime

The sensor functions like a chemical film: the interval between two readouts determines the exposuretime.

Application examples

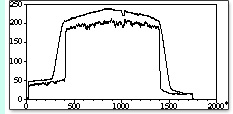

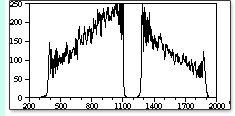

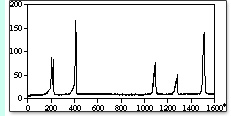

* On the vertical axis is the relative brightness with 8 bit resolution (0..255) plotted, on the horizontal axis the pixel number (picture element), that means the space coordinate in units of the pixel distance (here:12.7 µm).